Energy Efficiency with EC Fans & Motors

Electronically Commutated technology combining both AC & DC voltages to deliver efficient fan power.

Energy Efficient Technology with EC Fans & Motors

Axair Fans has established long term partnerships with manufacturers ECOFIT s.a. (France) and ROSENBERG Gmbh (Germany) and are able to offer Energy Efficient EC fans and air movement products. Both Ecofit & Rosenberg develop and manufacture their own motors and fans. The Ecofit EC range use motors from 65 up to 113Wa, the Rosenberg range use motors from 1.1 up to 3.4Kwa motors.

What is EC technology?

EC Technology stands for Electronically Commutated and combines AC and DC voltages, which is essentially a fan with a brushless DC motor, bringing the best of both technologies. The EC motor is running on a DC voltage but with a single phase 230 Volts AC supply (115 Volts option). The effect is minimum power consumption, infinite control possibilities (through 0-10V signal or PWM), but with a standard 230 volts 50/60Hz supply. Unlike the DC motor, which requires a separate controller (often considered as expensive, cumbersome and impractical), EC technology incorporates voltage transformation within the motor.

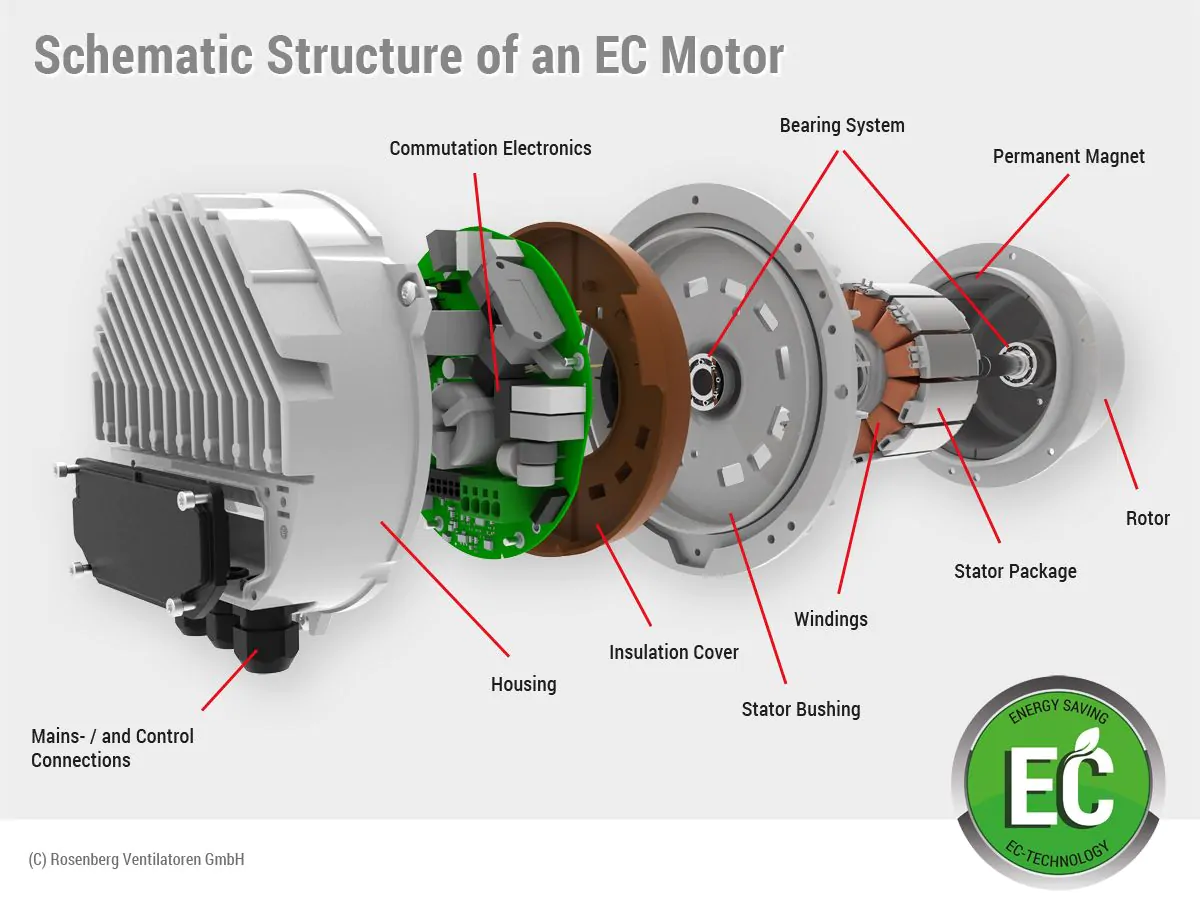

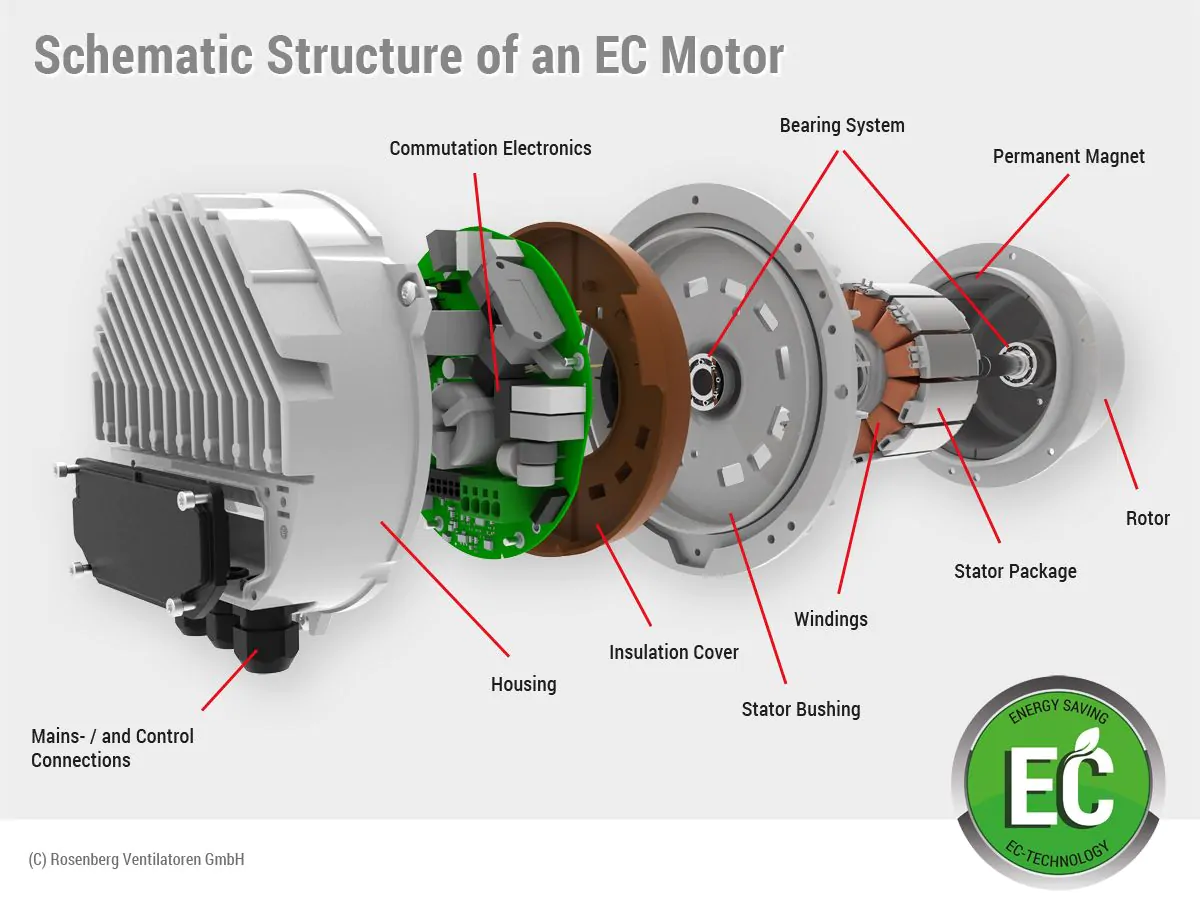

The non-rotating part of the motor (stator) has been extended to make room for an electronic PCB board which includes power transformation AC to DC, as well as the controls. The whole aspect is similar to a standard AC external rotor motor but with a slightly deeper base.

The results are reduced energy consumption producing an increased efficiency of 70% on current models (compared with 50% maximum in the AC single phase direct alternative). The electronically commutated motor can be offered with a number of options, such as Hall effect sensor or alarm output. The EC programming is also suitable for constant speed or constant pressure control.

DC motors already have low power consumption but if used in an AC application, the power needed to convert AC to DC, requires a bulky, inefficient transformer. The EC motor incorporates voltage transformation within the motor. The non-rotating part of the motor (stator) is extended to make room for an electronic PCB board which includes power transformation AC to DC, as well as the controls.

All the features of the external rotor motor are kept, including compact assembly, easy speed controllability, efficiency and characteristics.

EC Motor – Principle

With an EC motor the electronic circuitry stands in lieu of the traditional mechanical commutation meaning the right amount is being supplied in the right direction at exactly the right time providing precise motor control.

Permanent-magnet brushless DC motor within the rotor

The stator is driven by electronic switches (which replace the Carbon brushes), controlled by a microcontroller.

Electronic system (hall effect sensor or software is used to recognize the rotor position)

AC operated (230Volts Single phase or 380/480Volts 3phase, 50/60Hz)

Benefits

Energy savings : Minimum power consumption & better efficiency than AC equivalent.

Control : 100% speed controllable, not frequency dependant. Can be set-up for constant airflow or constant pressure applications, 0-10VDC or PWM control signal.

Low motor temperature : for longer lifetime than AC equivalent

Simplicity : Electronic & power transformation are completely integrated within the motor.

High performance : Speed can be driven up to 3600rpm, one EC fan replace multiple type of motors (2, 4 and 6 pole)

Easy connection : No complicated wiring and set-up with a Frequency Controller, EC fans have very little configuration.

Efficiency

EC technology motors have a near flat efficiency curve which barely varies across the speed range. A range of which is not limited by synchronous speeds or susceptible to voltage variations like its AC counterpart. Its AC equivalent will operate at a precise point on the curve which equates to its maximum efficiency, either side of this point and the efficiency diminishes.

Typical AC motors have losses in terms of power consumption (copper + iron losses), slippage and frictional losses (mechanical power). EC motor have no slippage losses, reducing losses and increasing efficiency.

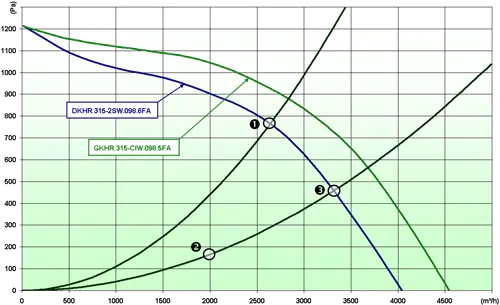

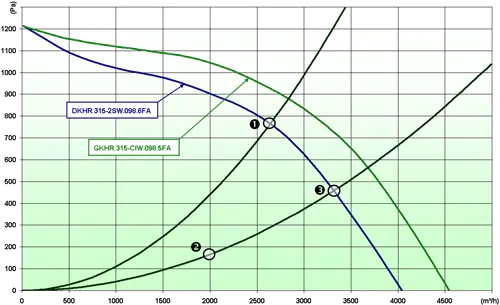

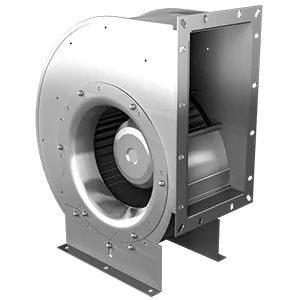

By comparing 2 backward curved centrifugal impellers, one in AC and the other in EC.

The Rosenberg EC Motor

The Rosenberg EC motor (EC = electronically commutated) is an inverter-fed synchronous motor with permanent magnets in an external rotor design. The AC mains voltage is rectified by the commutation electronics of the EC motor. A downstream inverter provides the motor with the motor voltage depending on the load, similar to the principle of a frequency inverter. In conjunction , all parameters of the commutation electronics and are optimally matched to each other. The intelligent EC commutation electronics decide how the motor windings in the stator are supplied with current (commutation) depending on the position of the motor, direction of rotation and speed set point. Permanent magnets generate the magnetic counterfield in the rotor, the torque required for rotation is generated from the interaction of the stator and rotor fields. A mounting flange on the rotor is used for stable impeller mounting. The simple and quick electrical connection is made either via a terminal box with cable glands or a connection cable, depending on the motor series. The use of deep-groove ball bearings closed on both sides with specially matched grease ensures maintenance-free and low-noise operation. The winding insulation meets thermal class F. Through the use of intelligent electronics, a wide variety of control and regulating functions can be taken by the EC motor depending on the area of application (infinitely variable speed control, pressure control, volume flow control, temperature control, air quality control).

ADVANTAGES:

- High Efficiency

- Low power consumption

- Integrated monitoring function (motor temperature, locked rotor and many more)

- Simple connection (Plug & Play)

- Expanded functionality (pressure control a.s.o.)

- Compact design

| Model | Fan/Motor Type | Supply |

Motor Power |

Speed |

|

DKHR 315-2SW-098

|

AC 3 phase fan 2 pole motor | 400Volts 50Hz | 1.52Kwa | 2750rpm |

| GKHR 315-CIW.098 | EC 3phase fan | 380/480Volts 50/60Hz | 1.41Kwa | 2950rpm |

| Model | Point 1 - 2603m³/h at 900 Pa | Point 2 - 2000mm³/h at 166Pa |

Point 3 - 3300mm³/h at 450Pa |

|

DKHR 315-2SW.098.6FA (Fan power)

|

Power : 1.42kW | Power : 0.62 kW | Power : 1.41 kW |

| Efficiency : 37.5% | Efficiency : 14% | Efficiency : 28% | |

| GKHR 315-CIW.098.5FA (Total power) | Power : 1.33 kW | Power : 0.27 kW | Power : 1.04 kW |

| Efficiency : 49.6% | Efficiency : 38% | Efficiency : 45% |

- The EC fan can rotate at a higher speed (2950rpm) than the AC (2750rpm) with a smaller motor than the AC fan (2.41 instead of 1.52Kwa)

- The data for the AC fan is the consumed fan power and excludes losses from any inverter or controller necessary to control the fan.

- The EC fan does not require any inverter or speed controller

Energy savings with EC fans

Let’s assume a laminar flow workstation requiring 13200m³/h at 450Pa. This requires 4 off Ø315 backward curved fans. Now let us assume that this workstation operates for 50 weeks of the year and for 8 hours per day at full speed. During non working hours to maintain the work area, the fans are run at roughly half the airflow.

Let’s compare the power consumed :

|

AC fan

|

2800hrs @ 4 x 1.41kW = 5.64kW | 15,792 kWh |

| 5600hrs @ 4 x 0.62kW = 2.48kW | 13,888 kWh | |

|

Total A 29,680 kWh

|

||

|

EC fan |

2800 hrs @ 4 x 1.04kW = 4.16kW | 11,648 kWh |

| 5600 hrs @ 4 x 0.27kW = 1.08kW | 6,048 kWh | |

| Total B 17,696 kWh | ||

| A minus B 11,984kWh saved with the EC fan | ||

Additional Functions

- Constant pressure : Used in conjunction with a pressure sensor, the fan maintains the same pressure at varying airflow (ideal for ducted applications). Operates with forward curved centrifugal fans without pressure sensor and with backward curved motorised impellers with pressure sensor (Available on Ecofit fans).

- Constant airflow : The fan maintains the same airflow at varying pressure (ideal for filtered applications) (Available on Ecofit fans).

- 0-10VDC / PWM output : EC motors can be controlled by a simple, standard 10kOhms potentiometer on the integrated 0-10VDC output (Available on both Ecofit & Rosenberg fans)

- Hall effect : A tachometric output is available, which can be used for an optional alarm relay (Available on both Ecofit & Rosenberg fans)

- Pressure control : A pressure sensor can be connected directly to the Electronic of the EC motor. The pressure control is made by the integrated electronics. No additional control unit is needed. (Rosenberg Versions only)

- Master/Slave : This system is used when several fans are used together within a single application. The main fan (Master) is individually pressure controlled. The other fans (slaves) are then speed controlled by the Master fan : Slave Fans are always at the speed of the master fan (Rosenberg Versions only).

EC fans from manufacturer Ecofit

Backward curved motorised impeller. Available in diameter Ø192, 220 & 225.

Forward curved centrifugal fan, Double inlet.Available in Ø160. Constant pressure or airflow configuration available.

Forward curved centrifugal fan, Single inlet. Available in Ø160. Constant pressure or airflow configuration available.

EC fans from manufacturer Rosenberg

Backward curved centrifugal motorised impeller. Available in Ø280, 315, 355, 400, 450, 500, 560 & 630. Can be used in the ECFanGrid.

Forward curved centrifugal fan – Single inlet. Available in Ø280, 315, 355, 400, 450, 500, 560 & 630.

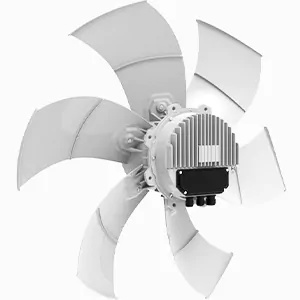

Axial fans – Available in Ø630, 710, 800, 900 & 1000. Several configuration available.

UNOBOX extraction / Ventilation units. Available in 4 sizes, Fitted with motorised impellers Ø355, 400, 450, 500, 560 & 630.

Roof fans with vertical discharge. Available in 3 sizes, Fitted with motorised impellers Ø355, 400, 450, 500, 560 & 630.